Story 2026/01/14

700 medicines are missing: How supply works despite shortages

What to do if an important medication is missing? Supply bottlenecks have long been part of everyday life in Swiss pharmacies. How Galenica is helping to secure supply in Switzerland.

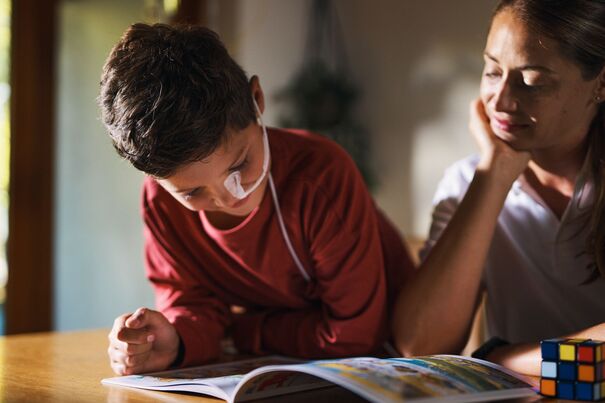

It is 8.15 a.m. in a local pharmacy in French-speaking Switzerland. Pharmacist Claire opens the delivery notifications as she does every morning – and once again a message appears: A pain-relieving and anti-inflammatory syrup is not available. A little later, a mother stands at the counter with her daughter, who is suffering from a severe ear infection. The prescribed medication is one of the medications affected by the bottleneck. Claire could send them away. But she decided differently and prepared the required syrup herself in the pharmacy’s laboratory – using traditional medical aids such as a mortar, scales and a measuring cylinder. Just two hours later, the girl receives the painkiller.

What seems like a rare exception is now commonplace in many Swiss pharmacies: they have to improvise, find alternatives and sometimes manufacture their own medicines.

A problem that affects the whole of Switzerland

Switzerland is currently experiencing more supply bottlenecks than ever before. More than 700 medicines are currently unavailable – from simple painkillers and antibiotics to medicines for complex therapies. The causes are varied and mostly global. Andreas Koch, Head of Wholesale & Logistics, sums it up: “We are seeing how fragile international supply chains have become. We are very dependent on active ingredient production in the Far East – and we feel the effects of this every day.” For pharmacies, this means additional work and constant uncertainty.

The federal government also recognises the urgency. It is currently working on a national strategy to improve security of supply – with more extensive compulsory stocks, a national early-warning system and strengthening domestic production. It is precisely these kinds of initiatives that are intended to prevent bottlenecks from going unnoticed or catching pharmacies and other healthcare institutions unprepared in the future.

"With our logistics, we can ensure that 99% of all available medications are available within one day."

Andreas Koch, head of Wholesale & Logistics

Galenica: the invisible backbone of supply

Hardly any other company influences the supply of medicines in Switzerland as strongly as Galenica. Through its wholesale subsidiary Galexis, the company supplies two-thirds of all pharmacies in Switzerland, as well as doctors, hospitals and care homes – and moves over 100 million packs each year. Andreas Koch says: “With our logistics, we can ensure that 99% of all available medications are available within one day. But the shortage of medicines is of course a major concern to us, as the products are also missing from our warehouses.”

Five approaches to secure supply

In order to address this shortfall, the Galenica Group is taking action on a number of points:

1. Together with authorities and manufacturers

Galenica is in close contact with authorities and international manufacturers to enable special solutions or imports. This interaction is essential to maintaining supply.

2. Higher stock levels – fast supply

The Galenica network maintains reserves of critical medications. These stocks help to bridge short-term bottlenecks and ensure stable supply to pharmacies. “When a product becomes scarce, we have to react immediately – redistributing, examining alternatives and providing transparent information. This is exactly where our sophisticated logistics systems and many years of experience come into play,” says Koch.

3. Data instead of surprises

With state-of-the-art operational and warehouse management systems and data from over 500 pharmacies, Galexis is able to identify trends that indicate bottlenecks at an early stage. This form of management will become increasingly important in the future – both for Galexis and for the national supply.

4. In-house production in pharmacies

In the absence of medication, pharmacies provide more intensive advice and manufacture certain prescription-only medications themselves, such as in the example described above. In Switzerland, all public pharmacies are permitted to do so provided they have the necessary cantonal operating licence.

5. Modern logistics as a safety factor

The degree of automation in Galexis’ large logistics centres is around 70% – ensuring efficient and reliable supply. In addition, there are innovations such as light-guided technology that directs employees to the correct item via a light signal, paperless processes, and a fully automated system that transports containers precisely to the picking stations. Koch explains: “Automation is not an end in itself. It helps us to make each individual process step more controllable and safer.”

Looking ahead: what Galenica continues to drive forward

The Galenica network is continuing to invest in storage capacity, new supply sources, digital tools for pharmacies, improved transparency and the modernisation of logistics centres. The company is also expanding its forecasting capabilities – including with the help of artificial intelligence. Koch says: “Our goal is clear: Switzerland should remain reliably supplied, even in challenging times. This is what we are working towards every day.”

The result: Security of supply remains a joint effort

All this shows that the medicine supply system only works if all stakeholders – healthcare institutions such as pharmacies and medical practices, authorities, manufacturers and logistics – work closely together. The Galenica Group plays a key role in this. With state-of-the-art logistics centres, strong partnerships, clear processes and reliable employees, the company ensures that essential medicines are available whenever possible.

Senior Communication Manager